USAGE

APT Polypropylene staple fiber has high tenacity, low englongation and extremely bulkiness, and also it is excellent for carding

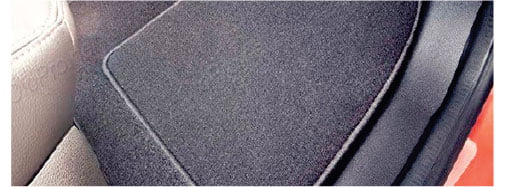

Automotive: car carpet, floor mat, trunk mat,…

Geotextile: high tenacity non-woven geotextile

Filtration: non-woven and spun yarn filter for both water filtration cartridges and industrial purposes

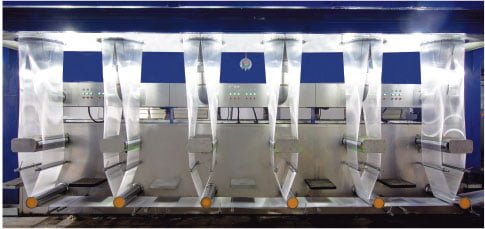

POLYPROPYLENE STAPLE FIBER PRODUCTION LINE

1. RAW MATERIAL

Virgin PP chips, raw material for polypropylene fiber are supplied and loaded into storage space.

2. SPINNING

Polypropylene fiber in the form of string is made by melting chips by heat and pushing through holes with pressure.

3. DRAWING

Rollers are used to pull staple fibers and stretch them to long sizes.

4. CRIMPING

Fiber strings will be crimped in hot oil to enhance the bulkiness, stylishness,…

5. DRYING & CUTTING

Staple fiber wet with oil will be dried and cut into regular lengths to made into cotton form.

6. PACKAGING

Staple fiber are packed in set quantities and shipment.

SPECIFICATIONS OF 6Dx100MM

| ITEM | UNIT | INDEX |

| POLYPROPYLENE INGREDIENT | % | 100 |

| DENIER | Dtex | 6.0+/-0.5 |

| TENACITY | G/den | 5.5+/-0.5 |

| ELONGATION | % | 60+/-15 |

| CRIMP | /inch | 6-8 |

| LENGTH | Mm | 100+/-10 |

| OIL PICK UP | % | 0.51 AVG |

| UV | % | 0.2 |

APT Fiber Factory can produce Virgin Polypropylene Staple Fiber as customer’s requirement, in black and white colour.

PACKING

+ Around 20 tons/ 1 container 40ft, 88 bales.

+ Weight: 220kg – 240kg/bale.

Tiếng Việt

Tiếng Việt